Optimise renewableenergy resources.

Solve biomass handling andcombustion challenges.

TAILORED SOLUTIONS

Biomass Fired Boilers

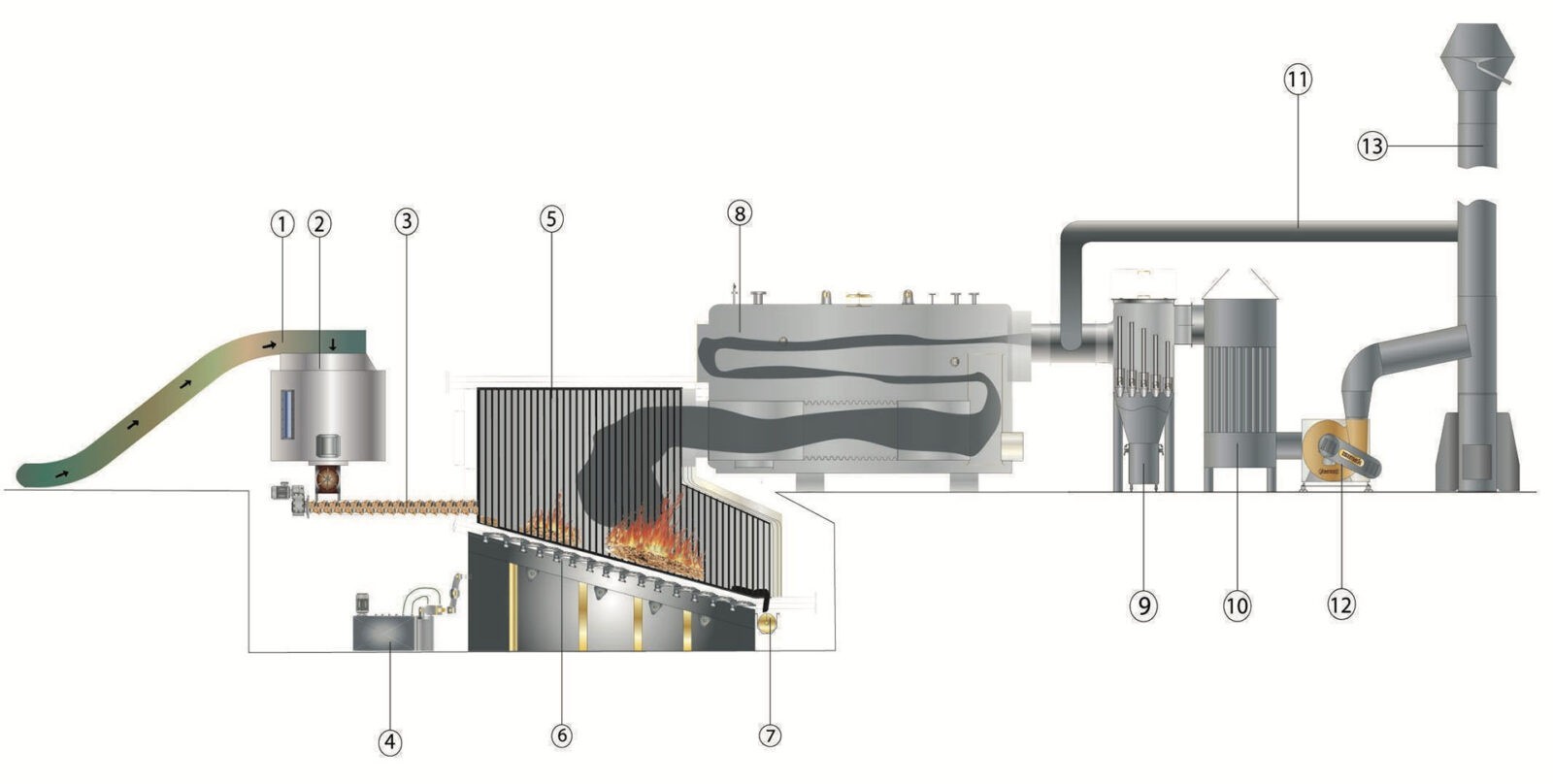

At Isimek we appreciate that each client’s requirements are unique, and we tailor our solutions to satisfy your specific needs. Our extensive experience with different types of biomass means we design solutions to meet all your biomass handling and combustion challenges. This includes the combustion of biomass with a high moisture content (up to 60%) or high ash content.

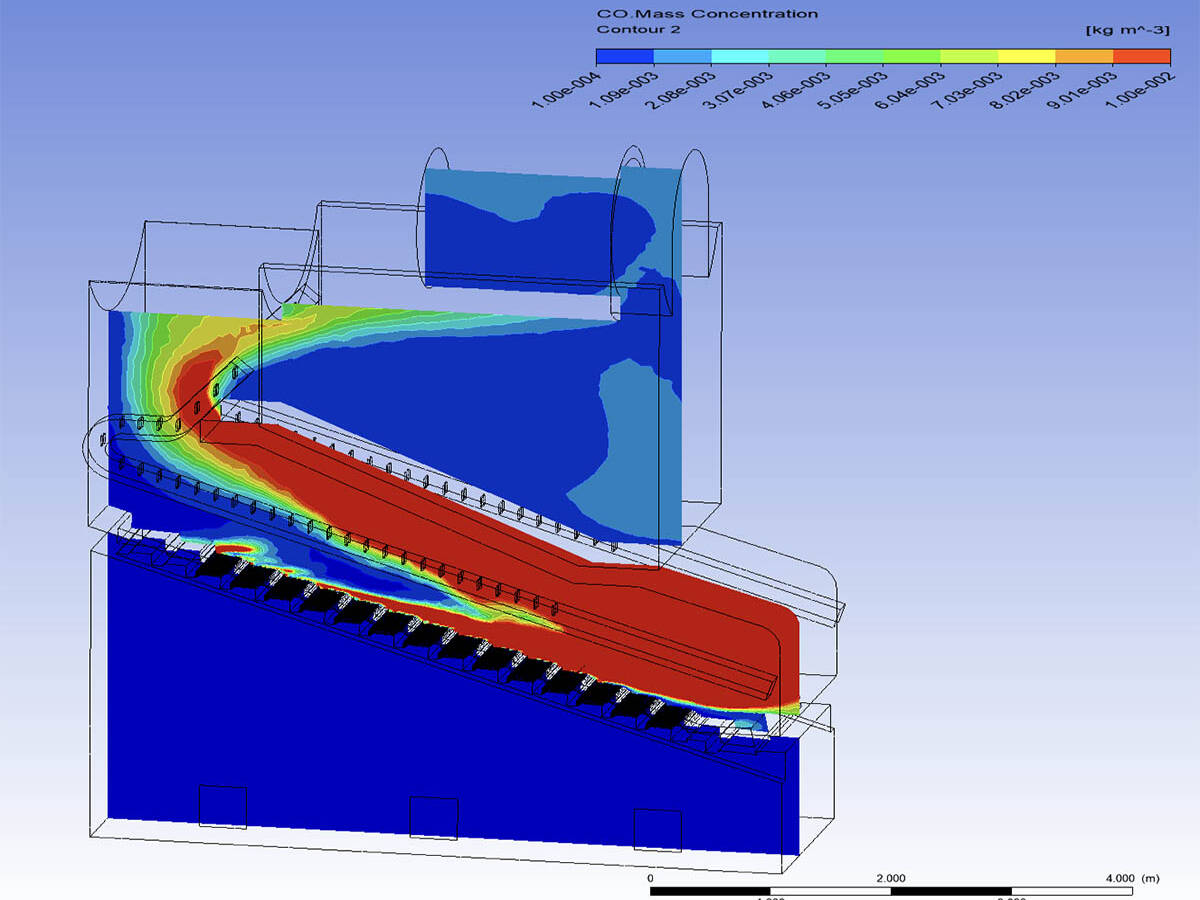

CFD ANALYSIS

Combustion efficiency

To ensure the successful delivery of each of our biomass boiler systems we carefully design each subcomponent. Biomass offloading, storage, handling and feeding into the boiler are all crucial to the operation.

With the increase in energy cost, it is critical that the boiler operates at the best possible combustion efficiency. CFD analysis is used to optimise the thermodynamic process inside the combustion chamber and gas flow through the boiler vessel.

BIOMASS BOILER TECHNOLOGY